In Case of Emergency

Coping with a flood of work.

Text:/ Derek Powell

Queensland integrator Advanced Video Integration (AVI) was proud to be helping the State Government prepare for future disasters with a comprehensive videowall, videoconference and signal routing project in the new state-of-the-art Emergency Operations Centre. But just part way through the build, the future became the present as the worst floods for a generation inundated the state. Suddenly, the Operations Centre was needed right now and the AVI installation team became part of the crisis response, frantically hand-patching feeds in real-time to emergency teams coping with an unprecedented scale of destruction. Then, with the crew at full stretch, they became part of the crisis itself as metres of muddy floodwater engulfed their Milton headquarters, devastating workshops, stores and IT systems. How AVI managed to beat the odds is a classic Queensland story that is already passing into audiovisual folklore, but the start of the project gave little hint of the drama to come.

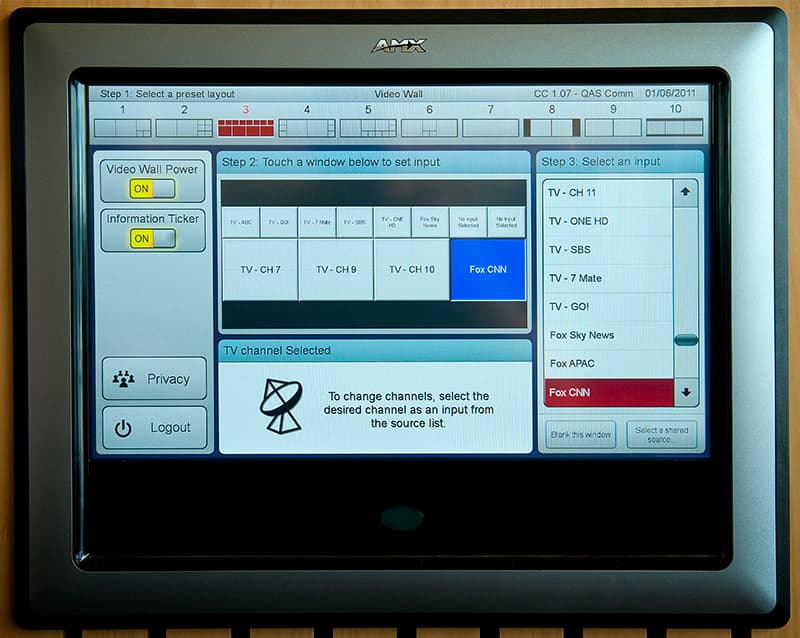

(main image above) The Queensland Ambulance Service Communications Centre (000 call centre). The video wall is an 8 x 3 array of Sharp 60-inch panels, and in common with all of the videowalls in the QEOC, is driven by a Jupiter Fusion Catalyst 4000 controller. And, yes, that’s Milwaukee 4, Cincinnati 2 at the bottom of the 5th. (Image courtesy of Advanced Video Integration.)

THEATRE OF OPERATIONS

The Queensland Emergency Operations Centre (QEOC) is officially described as “a purpose built world-class facility in line with best practice for highly effective communications centre management and disaster coordination”. The $78m project is the first purpose-built centre for emergency services in Australia and serves the Queensland Department of Community Safety (DCS), comprising Emergency Management Queensland, the Queensland Ambulance Service, Fire and Rescue Services and Corrective Services.

DCS managed the original tender for the project and AVI’s system design specialist Tristan Herrod recalled the initial site tour as a big event. “There were at least seven national AV companies there,” he noted.

The project was huge, comprising separate communications centres for Fire and Ambulance services, each with a massive 24-screen central videowall display, plus the State Disaster Management Centre comprising multiple coordination hubs with comprehensive presentation (including three more videowalls) and videoconference facilities. A total of 206 input sources and 158 displays were to be tied together. Any input could be allocated to any output, via a campus-wide video and audio routing system. There was also to be a full IPTV system which would include facilities for recording and automatic archiving of content.

The operational rooms needed to be able to call up live broadcast coverage of any unfolding disaster, but also had to be able to access any of the hundreds of traffic cameras operated by other departments, plus live pictures transmitted from emergency response vehicles on the spot. Clearly switching was the cornerstone of this project and Philip Holtum, AVI Managing Director, was quick to pick up on a potential contradiction in the documentation. “Probably the biggest change [we made] in the project was the switching and signal management outcome,” he observed. “We actually read the fine print that said the design must be robust and redundant with no single point of failure, yet the design was a single crosspoint switcher in the basement. That’s a pretty big single point of failure! If that fails, every single display in the building goes off-line… I don’t want to take that phone call,” Philip noted wryly.

MAKING THE SWITCH

The outcome was that the AVI team produced an innovative and elegant distributed switching design based on the AMX DGX-series fibre and DVI switching modules, and offered that to the client as an alternative. Their design featured a core 144 x 144 DGX fibre switch, trunked to eight 32 x 32 DGX switches and one 16 x 16 switch serving the major operational areas. Smart routing would be employed so that signals between switchers were managed intelligently, with the most efficient available signal path always selected. In the event of problems at the core, local sources would be unaffected while emergency patching could bypass faults to restore key services. It was a bold move, as the proposal was significantly more expensive, but the Department immediately picked up on the value offered by this more resilient solution, and awarded AVI the contract.

The next step was a comprehensive design review process. “What made it a great installation for us was the capacity to sit with the client and really understand their needs,” Philip reflected.

Tristan Herrod took up the story: “Post the award of tender, we ‘deep dived’ room by room. We actively encouraged and asked for interaction with the end users and we drilled down into what they were wanting, what they were expecting, what they felt they should have or could have… and we went through the entire project and heavily refined it,” he commented.

It was a tactic that paid dividends with the client. Dean Collette, QEOC ICS Program Manager, has gone on the record praising the cooperative way that AVI approached the job. “It’s not a project where I’ve felt we’ve got a supplier and us,” he stated. “It’s a project where the supplier has become part of the team and it’s just operated as a single team.”

WONDER WALLS

AVI involved the client every step of the way with numerous ‘proof of concept’ demonstrations for major hardware items like the 60-inch Sharp and 46-inch Mitsubishi LCD panels that formed the various videowalls. Installing the two major walls of 8 x 3 and 6 x 4 monitors was a precision task, involving laser levelling and millimetre precision for the mark-up of the mounting brackets. “It was a huge job,” recalled Tristan, “with the team spending more than a week working on each of those walls.”

The largest videowalls, one for the Ambulance and one for the Fire Communications centres, dominate their respective spaces in the building. Signals are processed using the Jupiter Fusion Catalyst 4000 video wall processors, in an Australian-first deployment of this technology. The system is flexible enough to allow any of the 12 connected DVI inputs to be displayed anywhere and at any size on the wall.

RESPONSE TO EMERGENCY RESPONSE

When the floods hit regional Queensland, the system was only at around 60% completion. The main program feeds were in place, but all signal switching was via the integrated site-wide routing system for which programming hadn’t yet been completed. The focus instantly switched from installation to support as the AVI teams scrambled to patch crucial feeds to the major coordination and control rooms. As the Premier and Prime Minister faced the cameras from the media room, AVI staff were feeding signals to the massive 103-inch Panasonic plasma that provided the backdrop and primary display for the press conferences.

Then the floods hit Brisbane itself.

From the second floor conference room at AVI’s Milton headquarters, Philip Holtum pointed out the high water mark, three metres above the car park. At the height of the flood, he rowed a dinghy up to the outside of the upper floor and smashed a window to get in and rescue crucial computer equipment. The ground floor, housing workshops, storerooms and training areas was totally destroyed.

“Probably the single most challenging part,” said Philip, in a masterpiece of understatement, “was the fact that we had to manage our own crisis while also resourcing the ongoing operations at the QEOC – and significantly resource them.” Today, there is little visible sign of the inundation and the workshop or store, and the training rooms are abuzz with activity. But freshly-painted besser-block walls have replaced the former plaster partitions – “easier to hose off, if the river ever comes back!”

GUI ELEGANCE

Back at QEOC, as the water receded, the programming effort was hitting high gear. “This is the only project, I’ve ever worked on where I felt we delivered a customised piece of software, not just an AMX program,” commented Tristan. Both he and Philip are full of praise for the work done by in-house programmer Jody Ernst.

Early on, AVI argued for the inclusion of a ‘super-user’ panel located at the main switching rack. The 19-inch ELO/TPI Pro2 system allows a top-down view of the entire facility, allowing monitoring of signals before and after switching and providing routing alternatives in case any single link should fail. The panel, and the enormous flexibility it provides for signal switching, naming conventions and permission setting, is the heart of the pioneering routing design. “The entire solution across five floors and two buildings is visible, controllable and dynamically assignable on that panel,” commented Philip. “We started there and worked outwards to the rest of the building.”

AMX touchscreens provide control in each of the 35 operational spaces, with a variety of panels ranging in size from 5-inch to 17-inch depending on the complexity of the control requirements. The user interface is simple and intuitive, yet astonishingly powerful. Central to the control philosophy is built-in redundancy, which preserves functionality wherever possible in the face of hardware faults or network outages. The program is designed so that one compiled source is sent to all masters and data is mirrored across all, meaning any data lost on reboot is reloaded from another master.

TRUE INTEGRATION

The integrated audiovisual systems at QEOC represent a huge technical achievement, even without the challenges faced by an installation carried out in the midst of the worst natural disaster in a generation and despite the inundation of AVI’s own facilities. The innovation and evident customer satisfaction with the results were recognised with an AV Industry Award for Best Installation (over $1m).

The last word should go to AVI Managing Director Philip Holtum, who rates the most satisfying part of the project as the “ability to forge a real partnership between builder, client and integrator”. Don’t we all wish for more projects like that!

EQUIPMENT LISTING

10 x AMX NI master controllers

44 x AMX touch panels

10 x AMX DGX fibre switch frames

82 x AMX DGX Rx modules

186 x AMX DGX Tx modules

AMX RMS room management system

1 x AMX Vision2 IPTV System

1 x AMX TPI Pro presentation interface

1 x 19-inch ELO touch panel display

48 x Sharp 60-inch specialist LCD monitors

36 x Mitsubishi 46-inch specialist LCD monitors

46 x Samsung LCD monitors (32-inch/65-inch) (approx. half interactive)

1 x Panasonic 103-inch Plasma panel

1 x Cisco C90 videoconferencing system

6 x Cisco C60 videoconferencing system

1 x Cisco C40 videoconferencing system

13 x Cisco Precision HD camera

4 x Jupiter Fusion Catalyst 4000 videowall processors

23 x video source devices (Foxtel, HD STB, DVD recorder)

4 x DVTel server/portals (acess to traffic camera networks)

1 x EYE12 Wolfvision high resolution ceiling camera

1 x BRCZ700 Sony HD PTZ industrial camera

15+ custom designed and manufactured mounting solutions

4 x ClearOne Converge Pro 880T audio conferencing system

2 x ClearOne Converge Pro 8i mixer expansion unit

1 x Biamp AudiaFlex audio processing system

AVI PROJECT CREDITS

Software Development: Jody Ernst and Gareth Sheard

AVI Technical Services/Engineering Manager: Richard Powers

Audio & VC Systems Engineer: Michael Mead

Site Managers: David Parker & Chris Weston

Plus the entire AVI team

RESPONSES