AV Case Study: BlueScope Port Kembla Steelworks

BlueScope Steel integrates Riedel Artist comms into its workflow, improving safety, efficiency, uptime and… wellbeing.

Text:/ Christopher Holder

It’s really quite something to be on the factory floor experiencing the BlueScope steel mill in action. It’s hot, loud and unrelenting. A 200m-long assembly line sees a red-hot 20-tonne steel slab getting cleaned, pressed and/or rolled into more usable product. At each point of the process, an operator oversees operations — visually (from a control booth called a ‘pulpit’) and via a phalanx of sensors and meters. Occasionally, something might go wrong — a machine malfunctions, the slab is the wrong temperature, etc. — and when it does, time is of the essence. The operator must identify the issue swiftly and immediately inform their counterparts up and down the line. Get it right, and it’s a glitch that can normally be rectified quickly and the process restarted. Get it wrong, and slabs become unusable and/or downtime is prolonged, potentially resulting in hundreds of thousands of dollars in lost revenue. Communication is key, and the stakes are high.

LEGACY COMMS

The Port Kembla BlueScope steel mill was built in the 1960s and until recently, the two-wire analogue partyline comms system was of that vintage. Scratchy and inflexible but serviceable, it did a job of sorts — complemented by a modern Tetra digital radio system for comms on the factory floor. But as the cable infrastructure inevitably failed, operators were forced to use landline and mobile phones to communicate. It was unsatisfactory and potentially unsafe. Benjamin Yeatman, BlueScope Hot Mills Electrical Engineering Team Leader, started scoping out a replacement comms system — something fit for purpose: “We started exploring options from different vendors and aligning them with our requirements. Key needs included: partyline communication, flexibility in call routing, and the ability to broadcast to all or communicate with individual pulpits.”

TETRA PART OF PACK

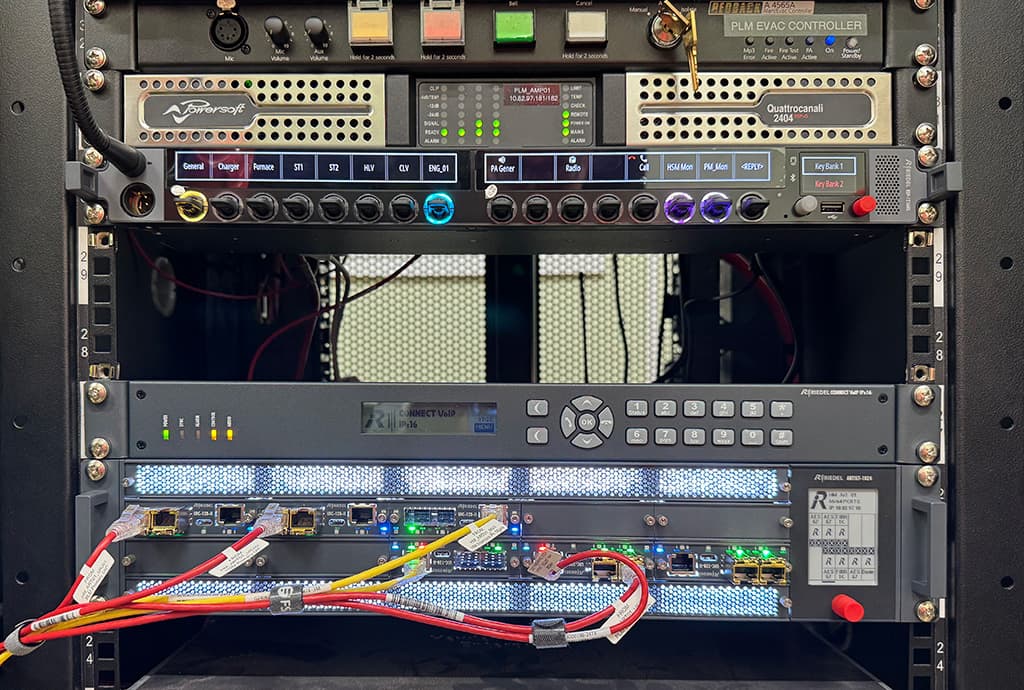

After careful consideration, Benjamin specified a Riedel Artist comms system. Riedel is synonymous with broadcast and events environments, and not so much with heavy industry, but Benjamin reckoned Artist was a perfect fit: “The old system was fixed to one channel and couldn’t be extended. With Riedel, we can tailor communication between pulpits, implement partylines, and integrate external hardware. The integration was seamless and enhanced communication across the plant.”

The integration with the existing Tetra radio system was especially important. As mentioned, prior to the upgrade, wired comms and the radio system were entirely siloed, and often operators in a pulpit and crew on the floor would communicate via their mobile phones. Riedel’s answer is something called Juggler Tetra, which seamlessly integrates the Tetra radio network into the wired intercom matrix, providing “intelligent integration between Tetra radio groups and Riedel Artist intercom ports”. The system allows calls from any port/group/conference of the Artist system to up to 64 individual Tetra radio groups — and vice versa. BlueScope Operations Manager, Karl Pajkovic, explains the payoff: “One big improvement is that we can now speak directly to floor radios. Before, operators in the pulpit had to use their mobiles while driving machinery — which wasn’t ideal, especially during critical safety operations. Now we have instant radio comms, which is safer and much more efficient. Breakdowns are dealt with faster, reducing downtime.”

“”

Now we have instant radio comms, which is safer and much more efficient. Breakdowns are dealt with faster, reducing downtime.

THIRD-PARTY INTEGRATIONS

Tetra isn’t the only third-party system that Artist is interfacing with. It also talks fluently with distributed speakers, microphones, and logic-based triggers via GPIO. These integrations allow operators to work with a control system that’s both responsive and intelligent, where audio signals are prioritised dynamically depending on the situation.

“We integrated external speaker and microphone systems, plus GPIs to trigger panel functions and prioritisation of audio streams,” explains Benjamin Yeatman. “It’s essential that operators hear the right information at the right time, and the system’s flexibility has served that requirement very well.”

Safety is paramount in a plant that deals with 1200°C steel and heavy machinery. The Artist system plays a pivotal role in the site’s emergency management strategy, ensuring that evacuation protocols can be executed without hesitation or confusion.

“Our evacuation protocol relies heavily on the intercom,” continues Yeatman. “Riedel allows us to prioritise emergency broadcasts, overriding any ongoing communication. That has been a vital feature – it ensures that during high-risk events, we can reach everyone instantly with a single press of a button.”

Beyond emergencies, Artist’s ability to layer and prioritise multiple audio streams — whether alarms, background music, or plant-wide announcements — helps ensure operational clarity. In a noisy, distributed site, clarity is everything.

“Whether it’s an emergency alarm, background music, or an evacuation broadcast, operators always hear the most critical signal clearly,” Yeatman concludes.

UPTIME LOOKING UP

The BlueScope steel mill is a 24/7 operation and downtime is costly, so service and reliability of any new comms platform was crucial. Benjamin Yeatman again: “Support was a core selection criterion. Riedel offers robust service‑level agreements and local support, which is critical for our 24/7 manufacturing environment. Reliability is also essential. Without comms, the process stops. Riedel’s built‑in redundancy in its Artist frames has proven to deliver excellent uptime and dependability.”

And tweaks to the system can be done on the run — no need to find downtime to make changes: “The system’s flexibility means we can respond to operational feedback in real time, adding functionality instantly,” explains Benjamin Yeatman. “For example, if we need to integrate an additional radio, it can be configured in under two minutes.”

MORALE BOOSTER

It’s astonishing just how quickly the team has fully adopted the Riedel Artist comms system. In fact, even before Benjamin and his team had finished commissioning the system, operators were already making good use of the Artist panels in the pulpits. Now, the system is essential and a natural part of the mill’s workflow. Operations Manager, Karl Pajkovic, noticed another interesting (and welcome) spinoff of the Riedel Artist integration: “Each pulpit can now communicate directly with another, which is crucial for clear communication. The audio quality is excellent – loud and robust – which is especially important in our heavy industrial environment where noise levels are high. But more than that, the comms is bringing the team together. Being alone in a pulpit can be pretty isolating, especially for new team members, but the Riedel comms allows us to include those operators and for experienced crew to connect even better. It’s good for morale.”

Riedel Communications: riedel.net

RESPONSES