Review: Alderwood Eros Pro

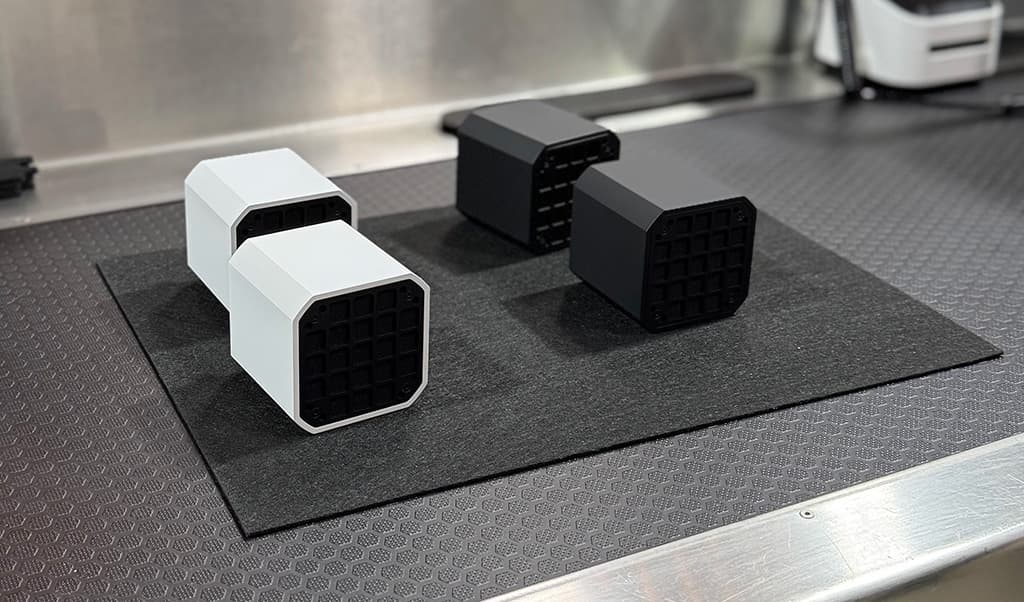

An Australian designed and manufactured miniature loudspeaker that’s built to withstand the rigours of virtually any commercial application.

Review:/ Christopher Holder

It turns out that 7cm x 7cm x 7cm are the ‘goldilocks’ dimensions. An enclosure any larger or smaller resulted in sonic compromises when working with these particular components.

Scott Wilkinson’s ears were the uncompromising judge, based on extensive prototyping. For Scott, nothing can shortcut the business of build it; test it; modify it; repeat. In fact, every aspect of this Alderwood loudspeaker has been prototyped for its audio performance, right down to the screws.

Alderwood boss, Scott Wilkinson, has been in the business of building the perfect miniature commercial loudspeaker for some five years now. In that time, Alderwood loudspeakers have become something of a darling of the marine sector – many a luxury yacht features Alderwood timber-ply cube speakers. The hospitality sector also love the low profile architecturally-friendly cut of the Alderwood jib.

LOVE FOR EROS

The latest offering, called Eros Pro, started life thanks to a glance through a component catalogue, where Scott spotted a HF driver with eyebrow-raising sensitivity, magnetic flux and frequency response specs.

The driver provided the basis of the new design. Scott and his team then spent months modifying the cone, the enclosure, the acoustic lens, the internal mounts and the porting. After painstaking prototyping, Eros Pro offers something like an ideal passive miniature cube loudspeaker for the commercial market. It’s tiny, it sounds wide and open, can be thrashed to within an inch of its life without a degradation in performance and doesn’t need finicky coupling to a sub or amp. In fact, any decent amp with a subwoofer output will drive the 8 ohm Eros. If you have a crossover, then 120Hz will about do it.

WELL MANORED

I first heard Eros Pro at the Alderwood factory in Cobden, about 60 clicks inland from Warrnambool in Victoria. The factory is built into a heritage cinema and hall that Scott and his wife have reanimated, hosting regular movie nights for locals. The Alderwood Manor AV offering combines a well-spec’ed Christie projector with a pair of Eros Pro miniature speakers mounted to the front wall, paired with an Alderwood directional sub. There’s no way the Eros+sub combo has any right to fill the hall with hi-def sound but it does.

The 120° conical dispersion is as wide as Scott wants to go before unwanted reflections from surfaces behind the unit started to noticeably smear the image. The outlandish sensitivity of Eros Pro is also great for movies and music alike.

Arguably the valved port design is this speaker’s secret sauce. Not only does it act as a port to extend the bass response, it dynamically controls air pressure within the tiny enclosure, allowing the comparatively big magnet assembly to move the coil at full tilt without ripping the driver apart. In fact, in the Alderwood factory tests, Eros Pro can happily go hard at least 12 hours a day, seven days a week without slowing down. It’s this feature that really makes Eros Pro suitable for just about any commercial application.

The IP53 rating is also useful and makes Eros Pro suitable for most outdoor applications.

And finally, the aluminium box with its ceramic paint coating is bullet proof. Eros Pro feels very solid and professional.

MORE INFO

Alderwood Eros Pro

Miniature Passive Loudspeaker

CONTACT

Alderwood Speakers: alderwoodspeakers.com.au or 0419 097 092

TALK IT OUT

You can a transcript of my interview with Scott Wilkinson later in this article and for anyone interested in loudspeaker design, it’s an interesting read. Here’s a local talent who has established a cool, made-in-Australia business and is finding a real niche for his engineering chops.

Yes, there are other small-format, sub/satellite loudspeaker systems out there. Doubtlessly there are cheaper alternatives as well. But few will be as well suited to the constant punishment these Alderwood Eros Pro units have been designed to withstand. Even fewer will include a beautifully milled brass ball joint for mounting. And few will sound as lively and as articulate as these.

If you’re curious, I can recommend a drive out to Cobden for a listening session with Scott. Hearing is believing.

Tiny Speakers, Big idea: An interview with Scott Wilkinson, Alderwood Speakers

AV: Alderwood is almost exclusively known for its miniature speakers. What put you on that trajectory?

Scott Wilkinson: Actually, I used to build tower speakers – the bigger, the better. If it took two people to lift it, that was a win for me. We had subs with the surface area of equivalent of twin 12-inch drivers. I was working with Tymphony’s LAT700 technology – stacked drivers connected with carbon fibre rods.

That was a 10-year journey – chasing the perfect big speaker. Meanwhile, my wife had been hounding me for six months: “I want a small cube speaker.” Eventually she slapped $500 on my bench and said, “I’m a paying customer, give me my speaker.”

I told her to keep her money, went to the shed one Sunday, and built a little sub and two very rough cube speakers. I didn’t measure them, I just threw them together and gave them to her. I popped them on top of the tower speakers, turned them on, then walked to the kitchen at the other end of the house and noticed it was still really loud.

When I got back, my wife and brother were on the couch and said, “Hate to tell you this… but we prefer the cubes.” I was annoyed, so I took them back to the shed, measured them, and realised: the on-axis response was good, and the off-axis response was still solid. That was surprising – most speakers drop off in the highs off-axis. Silk domes are okay, but they don’t project much. The two-inch diaphragm on this particular unit could really throw high frequencies.

That was the turning point. I spent the next three years perfecting the design, shrinking them down, and understanding what made it work – and what didn’t.

AV: That explains your small-speaker fascination. What’s the origin story for this new product, Eros?

Scott: FaitalPro reached out to us probably about 12 months ago. They wanted to share their OEM catalogue. I was scrolling through it and noticed a new driver – it had really high sensitivity specs, quite good low-frequency extension, and it was only two and a half inches across. A few months later we got our first production run to work with.

In our tests this new driver was particularly difficult to work with – not because of strength, but because of its unique design. With small drivers, you need a manufacturer who knows how to do glue joints properly. The forces on those joints – especially where the voice coil attaches to the cone – are just so much greater than with a standard-sized speaker.

AV: Why is that?

Scott: Take a large sealed box – it has a lot of air compressibility. There’s some give. But a smaller box has very little compressibility – there’s no give. So the first point of stress becomes the glue joints – pressure builds up and stresses the structure.

AV: Sounds like you went through a bunch of drivers on your way to finding the right design?

Scott: Our prototyping process involved building around 200 designs. We don’t get attached to any of them – we build, listen, test, measure, and put them through a power response test. Our products get absolutely tortured all day, every day, especially in commercial use.

You might find a box that sounds sweet at 1W but completely falls apart at full power. So we’re also testing how well a design fills a space. That’s the kind of performance people expect from us.

AV: Sounds like a paradox: small speakers filling a large space.

Scott: Yes. But smaller speakers have excellent off-axis response, so they can very effectively fill large spaces. Larger speakers tend to beam more. You can use lenses and other tricks to correct for that, but anything you put in front of the driver potentially introduces distortion.

AV: What else makes a small speaker feel like it fills a space?

Scott: You need a high-sensitivity driver to begin with. If sensitivity is too low, you run into power compression – basically creating heat instead of sound. Some small speakers fail in that regard. That’s why we tune everything at max volume – we want peak performance at full power, not just at 1W. A driver that would fall apart on a test bench survives once enclosed and can run for 10–12 hours straight.

AV: Why is that?

Scott: We fine-tune our enclosures with a valve system that regulates airflow and pressure. It controls excursion – like a passive servo system. It prevents excess power from hitting the driver at its tuning frequency. So it’s like a passive crossover, but with no components – keeping phase coherence and simplicity.

AV: So you started with a sealed box?

Scott: Yes. The sealed box was our baseline. Around 70% of our speakers are used outdoors or on boats, so we needed weather resistance. But sealed designs have limits – especially in bass extension. Even a standard ported box gives you 3dB more at tuning. This new design is all about extracting the maximum possible performance from a small enclosure. Compared to our previous design, our new speaker delivers a 12dB gain from 500Hz down to 80Hz. That’s a huge difference. We didn’t have much at 80Hz before – it’s not a full-range speaker, but it allows us to use a much lower crossover point where it hands over to a sub.

AV: That extended response in the 80-500Hz range, is that primarily down to the FaitalPro driver?

Scott: Partly. But more so our ability to modify the driver. We don’t use anything off-the-shelf – we make several adjustments. With small speakers, even minor changes make a big difference. For instance, if you bolt a speaker directly to the enclosure, you couple it – vibration reflects back into the driver, creating resonances.

So none of our screws touch the driver. It’s fully encased in rubber, completely decoupled from the cabinet. I picked up that idea from Japanese audio design back in the mid-90s. They used nylon bolts with limited torque to minimise resonance in horn-loaded enclosures. That stuck with me.

Now we use a gentle clamping mechanism. Our pass/fail regime is strict – too much torque and the driver fails. It’s that sensitive.

AV: And makes it more robust when shipping them around?

Scott: Yeah, exactly. We don’t want a speaker that’s going to fail if it gets dropped or knocked about. Honestly, the first test we do is a drop test – it has to survive that.

AV: Anything else going on inside the enclosure?

Scott: The internal wiring is all pure silver cable – the kind of thing you’d find in ultra-high-end headphones. Not because it sounds superior now, but because of how it performs in 10 years’ time.

If you strip a cable and touch it with your fingers and leave it for six months, you’ll see oxidation where your skin contacted it. The acids in your skin reduce conductivity – about 30% over two years if copper terminals are touched. It’s been studied, but no one talks about it. In our process, no human skin touches any terminals.

I personally like silver because it’s the best conductor available, though it can make some speakers sound too bright. With our speakers, you don’t have to worry about crossover interaction – we don’t use any. They’re an easy 8Ω load with high sensitivity, so they’ll work with almost any amp. That sensitivity means you’re in danger of hearing more distortion from your amp, but also more detail from a great amp. That’s the upside of high-sensitivity designs.

AV: What are the dispersion characteristics of Eros?

Scott: 120° conical. In our previous design, we pushed for very wide dispersion — nearly 170° at -10dB. That was impressive, but it introduced problems. You’d pick up reflections from the wall it’s mounted on — out-of-time reflections.

We settled on a 120° conical dispersion. We’ve developed a range of lenses for different applications — some tight-focus, some wide. Being a niche manufacturer, we get all sorts of requests. The 120°x120° conical pattern is a good compromise. It covers the room effectively without picking up too much from nearby walls — just keeps it focused forward.

AV: What are the demands of the commercial market compared to, say, the hi-fi or residential space?

Scott: In commercial, the speakers are turned on first thing in the morning and run at high volume all day — in pubs, that can be 14 hours a day, non-stop. So the products have to be robust and reliable.

They need to look the part as well. With commercial venues, it’s often architects saying, “I’m not having a black box on the wall. Find me something else.” That’s where we found our niche.

Architectural audio — delivering great performance without visual compromise. If the speaker is visible, it needs to look good. If it’s hidden, it still needs to sound great.

Sometimes it’s also about practical constraints. Low ceilings, for example, mean they need an on-wall speaker that can be angled properly.

These are well made and outstanding performance for their size. Particularly for acoustic music and vocal projection.