Amway Calling

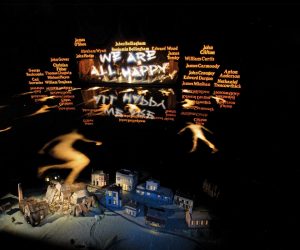

The Amway China juggernaut rolled into Melbourne. Staging Connections put its best screen forward.

Text:/ Brad Watts

Earlier this year, Staging Connections had to think big. Not as though it’s unaccustomed to large productions, but when Staging Connections created Australia’s largest flat projection screen for a series of massive Amway China business sessions in Melbourne, it really had to pull out all stops to keep the series of shows on track.

The 46m-long, 6m-high screen was the visual highlight of the gigantic set, delivered by Staging Connections to meet the client’s exacting requirements. The venue was the Melbourne Convention & Exhibition Centre, with a jamboree that included around 7000 Amway delegates spread across four separate events. Staging Connections had worked with Amway on three incentive events in the past, but this show proved to be the biggest and most demanding production to date.

FROM CHINA WITH LOVE

Amway China gave Staging Connections a very precise brief, with Staging Connections providing all AV, set construction and theatre infrastructure to deliver the required pizzaz. The technical brief involved the immense screen, full control equipment, projection and control towers, along with a high quality audio system and static, room and intelligent lighting.

Various sections of the show required bespoke constructions, such as a custom-made stage, a custom lectern and a backlit front logo panel, as well as stairs to and fro the various levels of staging.

On stage, massive letters backlit with special LED strips spelt out the word ‘Melbourne’ – in both English and Mandarin.

With an eight-day bump-in, a crew of over 50 technicians and staff to set up and pack down the event, a technical operation crew of 15 local and Chinese technicians to oversee the sessions, you get some idea of the enormity of the task – building the largest projection screen in Australia was no mean feat. AV spoke to Staging Connections Technical Director Andrew Maccoll about some of the whys and wherefores behind pulling off such a spectacular.

RIGOUROUS

AV: So what did this massive video rig consist of Andrew?

Andrew Maccoll: Video-wise there were six Christie 20k Roadsters which were backed up with a further six Barco R12s. The projectors each run with control software via dedicated PCs so we could power them up and down using a combined wireless and wired backbone network.

There were seven Folsom Encore Presentation Systems, then within the Encore rig there’s a 16 x 16 analogue matrix switcher and an 8 x 8 DVI switcher, and an 8 x8 HDSDI matrix switcher – then there’s the Encore controller. We also run an uninterruptible power supply over the Encore system just to make sure nothing goes down during the show. Then there’s 14 Dataton Watchout PCs. That consists of two complete Dataton systems, seven of which are required to do the main work, with the other seven on standby should the main system go down. Then there’s a Sony DFS-800 for vision mixing and a full broadcast camera string of three cameras hanging off the end of that.

Replay was via GrassValley Turbo hard drives, again two of those were dedicated to backup duties. There were some presenters that used Powerpoint for their slide presentations, so we had four dedicated graphics PCs for presenters’ slideshows. Those presentations were executed via the Encore system. Again, all that gear was all powered via UPSs in case of power failures. Plus, with such a long startup time for all those PCs, basically too slow to recover from a power failure, there was no option but to keep everything powered redundantly.

AV: The Dataton Watchout systems took care of the blending of the projections?

AM: Well actually we’ve found we get better results from the Encore system. The Watchout systems will do a blend but we find it easier not to rely on that because we’re running so much additional content. We’ve got video running from hard drives and IMAG, and that footage has to run across the blend as well. So the Watchout is running ‘background plates’ if you will. All the large graphics and all the ‘walk-in/walk-out’ videos that are playing during the opening and closing of the show. Then when there’s a window of, say, somebody speaking or a set of Powerpoint slides, those images are being dropped in downstream by Encore – so that’s managing all the blending duties.

We were pretty much at the limits of what we could achieve with Watchout. With trying to synchronise six hard drives and six video cards with Watchout you’ve got to have the host machines very highly spec’ed with RAM and video capabilities, so it become a tough ask. Plus, running at higher resolutions will actually fracture the image and you’ll see it all start to come apart when you least expect it.

AV: It’s a huge rig…

AM: It certainly is. It’s a lot of gear, and this is the area where we always find ourselves having to balance things up. Whether or not we can do without certain bits of gear. I’m a big fan of keeping these things as simple as possible as it usually works better, but in this case the scale of the show required a huge assembly of equipment.

AV: Was this the largest screen Staging Connections has put together?

AM: Well we regularly do 18m by 16m screens with a three projector blend – that setup is a very standard corporate show that we’ve installed for countless venues around the country. We’ve done work using cycloramas up to 25-odd metres wide, but nothing quite this big. We’ve also done very large projection blends. For example, we did a tourism event in Adelaide where we used seven projectors blended together, but that was primarily for scenic backgrounds, what we refer to as ‘wallpaper’ – montages of imagery basically. However, in those situations the screen surface isn’t as critical, nor is having such absolute image reproduction. The Amway shows are certainly the biggest screen fixture we’ve done to date.

TRIM & TERRIFIC

AV: Audio must have been difficult with such a large expanse between speaker arrays. What system did you use?

AM: We used EAW and there were plenty of difficulties faced by the audio crew. For starters the trim height had to be quite high because the projection beam has to reach both the top and bottom of the screen. Normally when you hang a line array you’re not that concerned about projector beam widths and you can have your cabinets hanging quite low into the room. The brief for the audio crew was firstly to avoid interrupting any sight lines between the audience and the screen, but also to not impede the projection beams. Complying with those restrictions can be difficult but the crew managed it in style.

In terms of gear they used 18 EAW KF730 SLAM (Small Line Array Module) units for the array modules, then six EAW SB218s sub on the floor. So the system sound and dispersion was actually very good. The modules were flown above the screen but tipped down quite low. For the tiered seating sections of the audience this worked very well but one issue that did crop up was in the very front rows where the VIPs were seated. Because those patrons were out of the line array beam there’s a number of speaker cabinets built into the underside of the stage specifically for addressing those front rows.

SCREENING PROCESS

AV: Can you fill us in on some of the logistics involved with the actual screen surface?

AM: Well the surface is a purpose designed fabric made by Screen Technics in Australia. They’ve goT the facilities to manufacture a surface of this size – it’s a plastic-style material that’s welded with invisible joins. What you end up with is an enormous plastic sheet with eyelets around the edges. The eyelets are used to mount the screen and pull the screen tight against the frame. The frame was constructed from 300mm box-truss supplied by Bytecraft Entertainment. Then our guys cable-tie the surface to the frame. So everything is put together flat on the ground, we then do the top and the sides, then raise the screen into a vertical position because the surface then has to stretch out for a few days. We then pull it up vertically, to just above working height, cable tie the bottom and let it sit for another day while it stretches out some more, after which we re-tension the whole thing again. Once we’re happy, the screen is then flown out to the trim height and left to hang for another couple of days while we fine tune it.

Obviously you can’t have any creases, so the span-sets when flying it have to be done in such a way that it doesn’t cause any further warping and create more wrinkles. It’s so finicky that even where you have the trussing joining together, those joins can end up standing out slightly, so it becomes a bit of a juggling act.

AV: Image stabilisation is always an issue. Were there additional headaches involved with a projection screen of this size?

AM: Well, yes, this is always the big issue with large projection shows, especially when you’re blending images. Even a slight movement in the concrete slab can affect the positioning of a projector. In some venues large movements of people, or even a forklift working in an adjoining area can affect the projector positioning, and consequently the resulting image. Plus there’s the movement within the scaffold tower which can compound those changes again. The answer to all this is: constantly check and readjust the rig. Our crews would check the lineup in the morning then recheck every lunch hour. To keep the standards that we’re looking for, the video crew would conduct their adjustments using a pair of binoculars. They’d check the focus and check the lineup of the blend sections. The Christie projectors were approximately 32 metres back from the screen, so there’s a plenty of margin for error even after you’ve compensated for any movement.

AV: Can the surface material be reused?

AM: We can reuse it, and yes we still have the surface, so that can be redeployed when required, but obviously only for an engagement that needs a screen of that size. We’ve had a couple of inquires already but it’s a big job – the screen material alone travels between venues on its own pallet and weighs about 160kg. It’s like dealing with a 160kg, brilliant-white pool liner.

RESPONSES